COATED BLADES

#11 ZrN Coated Hobby Knife Blades

#20811Excel Blades #11 ZrN Coated Hobby Knife Blades - Multi Pack, Carbon Steel, Exacto Knife Compatible Unleash unparalleled cutting performance with th...

View full details#11 TiN Coated Hobby Knife Blades

#20411Excel Blades #11 Titanium Nitride Coated Blade Our most popular blade, now with an added edge! This versatile double-honed blade features a durable...

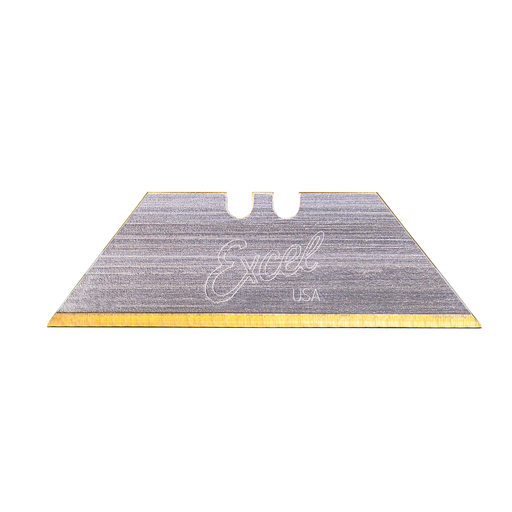

View full details#92 TiN Coated HD 2-Notch Utility Blade

#20492Excel Blades #92 Titanium Nitride Coated Utility Blade Upgrade your utility knife with our enhanced #92 Heavy Duty 2-Notch Utility Blade, now featu...

View full details#16 TiN Coated Stencil Edge Blade

#20416Excel Blades #16 TiN Coated Stencil Edge Blade – Double-Honed, USA Made Achieve sharp, accurate cuts with the Excel Blades #16 TiN Coated Stencil E...

View full details#21 TiN Coated Stainless Steel Blade

#20421Excel Blades #21 Titanium Nitride Coated Blade Experience superior cutting performance with our enhanced #21 blade, now featuring a premium titaniu...

View full detailsStay Sharp, Stay Protected: Coated Blades for Every Precision Cut

Whether you're a crafter, hobbyist, or professional, these high-quality blades ensure precision cuts while maintaining their sharpness and strength. With advanced coatings like Titanium Nitride (TiN) and Zirconium Nitride (ZrN), our blades offer exceptional longevity, and corrosion resistance.

Benefits of Knife Blade Coatings

Coated blades are designed to last longer, resist rust, and reduce friction for smoother, cleaner cuts. By adding a protective TiN or ZrN layer to our blades, we enhance blade longevity, minimize wear, and ensure top-tier performance for crafters, model makers, and artists. Whether you're working with paper, plastic, foam, vinyl, or other materials, Excel Blades’ coated blades provide superior strength and precision.

TiN vs. ZrN: What’s the Difference?

Excel Blades offers two advanced coatings to meet different cutting needs:

-

Titanium Nitride (TiN): A tough, wear-resistant coating that extends blade life and reduces friction for ultra-smooth cutting.

-

Zirconium Nitride (ZrN): Offers the same durability as TiN but with even greater rust and oxidation resistance, making it the ideal choice for humid environments or long-term storage.

Both coatings provide exceptional sharpness and edge retention, helping crafters, model makers, and professionals achieve clean, controlled cuts with ease.

Discover Excel Blades' Superior Coated Blades

From #11 precision blades to more heavy-duty cutting blades, Excel Blades’ coated collection delivers professional-grade performance with rust-resistant protection and extended blade life. Upgrade your toolkit with blades designed to stay sharper, longer and shop our collection today!

Frequently Asked Questions

Is it Better to Have a Coated or Uncoated Knife Blade?

Coated blades provide better rust resistance, longer lifespan, and smoother cutting compared to uncoated blades, making them ideal for precision work and frequent use.

What Is the Best Blade Coating?

TiN and ZrN are both excellent options. TiN offers superior wear resistance, while ZrN provides enhanced corrosion protection. Your choice depends on the cutting conditions and material you’re working with.

Is Titanium Nitride Stronger Than Carbon Steel?

Titanium Nitride is a hard, wear-resistant coating that enhances the durability of carbon steel blades, making them last longer and perform better under heavy use.