Custom Manufacturing

A tool for every craftsmen, company, and industry.

A tool for every craftsmen, company, and industry.

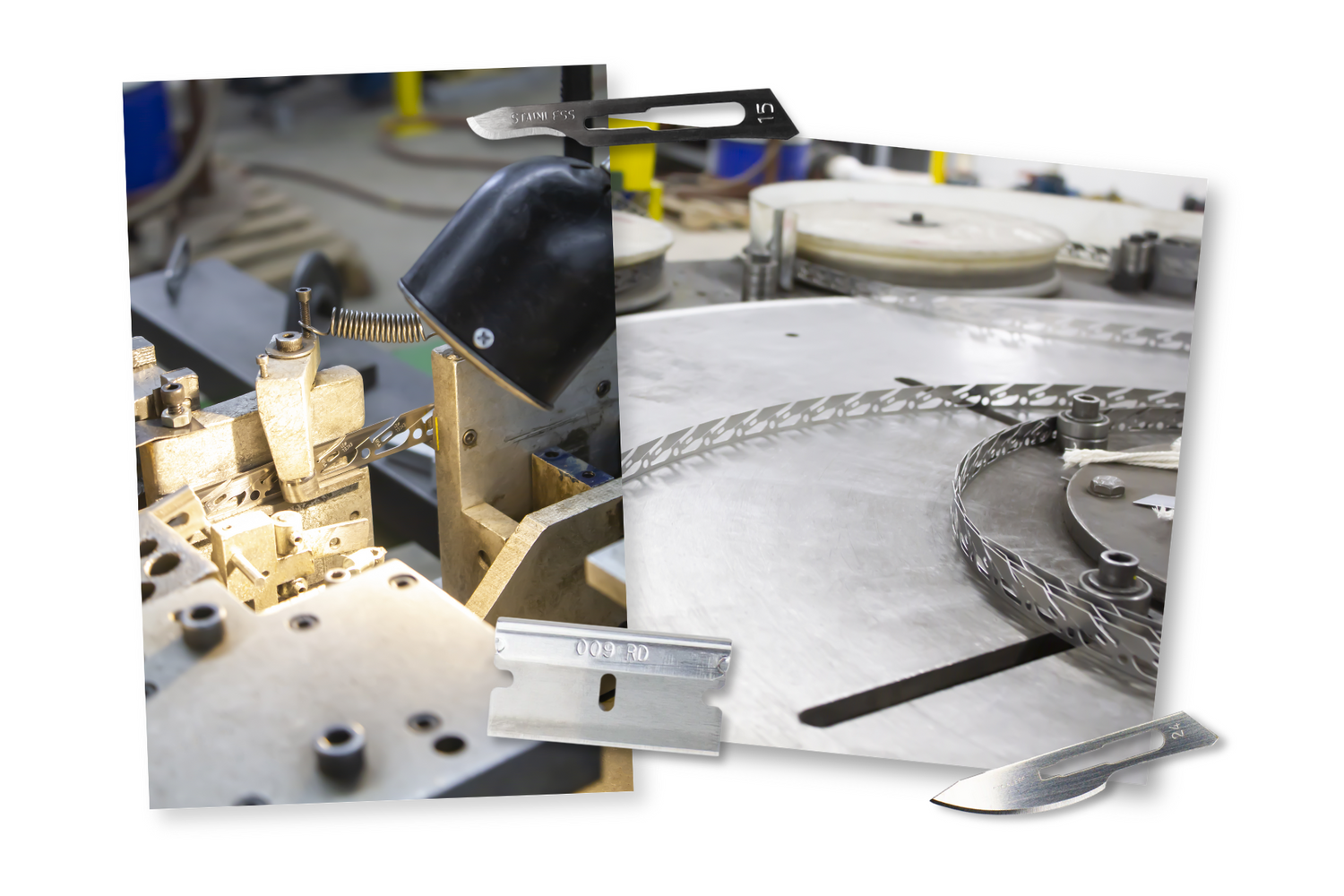

Excel Blades is a leading North American manufacturer of knives, blades and hand tools, and is the only U.S. Based manufacturer of precision knives. We are dedicated to providing customers reliable, durable and precision tools.

Whether you are slitting plastic sheets, trimming flashing, cutting carpeting, stripping wire or scraping glass and flooring, we can engineer and manufacture high-quality blades for your custom application.

Excel Blades produces a wide variety of industrial and specialty cutting blades to suit diverse applications. We manufacture:

•Slitter Blades

•Blunt Tip Blades

•Rounded Tip Blades

•Hook Blades

•Breakaway Blades

•Snap-Off Blades

•Injector Blades

•Razor Blades

•Angled Blades

•Precision Hobby & Craft Blades

Need something custom? Reach out to our Custom Blade Engineering team for a tailored solution at info@excelblades.com.

Yes, Excel Blades specializes in bulk blade manufacturing for high-volume production runs, while also accommodating small-batch and specialty custom blade orders for niche applications.

We deliver custom-cutting tool solutions across industries, including:

•Sign & Vinyl Graphics

•Industrial Manufacturing

•Hardware & Tools

•Arts, Crafts & Hobby

•Textile & Apparel

•Aerospace & Defense

•Packaging & Converting

•Biomedical & Laboratory

Learn more about our industry expertise and the industries we serve on About Us page.

Yes. Excel Blades can reverse engineer and match legacy or proprietary blade designs from physical samples or technical drawings. Contact us at info@excelblades.com to initiate a blade replication assessment.

We work with:

•Carbon Steel for superior sharpness and durability

•Stainless Steel for corrosion resistance

•Optional coatings include: Titanium Nitride (TiN) and Zirconium Nitride (ZrN)

Explore our Product Catalog to learn more about our Metals & Blade Materials.

Yes, based on project scope. We offer blade prototyping and pre-production sampling to help you validate design, tolerances, and functionality.

All Excel Blades products are proudly manufactured in Paterson, New Jersey, under strict quality control protocols. Check out Excel Blades' Google My Business Profile for more information.

Yes. Excel Blades is a trusted name in USA-made precision cutting tools for both commercial and industrial use.

Check out Excel Blades' Google My Business Profile for more information.

Yes. Excel Blades offers OEM and private label blade manufacturing, including custom branding, labeling, and retail packaging. Fill out our Custom Solutions form to get more information.

Yes. Our team provides comprehensive support, including:

•Custom Blade Design

•Tolerance & Material Guidance

•Tooling & Mold Development

•Performance Testing & QA

Collaborate with our engineers to achieve optimal cutting performance.

Lead times vary by project:

We focus on efficient production and clear communication to keep projects on track.

Pricing depends on:

•Blade material (e.g., stainless vs carbon steel)

•Order volume

•Custom tooling and labor

Pricing depends on factors such as material type, order volume and labor involved. Stainless steel is typically more expensive than carbon steel. We'll review your project and provide a detailed quote.

Request a free custom quote using our form.

Yes. We ship via parcel, LTL or FTL based on your needs. We'll work with you to determine the best, most cost-effective shipping method.

No. Excel Blades provides free, no-obligation quotes for all custom blade inquiries.

Yes. We manufacture both 2-facet blades (ideal for durability and general use) and 3-facet blades (engineered for high-precision cuts). Contact info@excelblades.com with your exact specifications.

Yes, we accept blanket POs with scheduled releases, enabling efficient inventory planning and production coordination.

We highly encourage this as blanket POs help us plan material procurement and production scheduling more efficiently.

Yes. Excel Blades offers in-house thermoforming, blister packaging, and custom labeling to ensure your products are retail-ready.

Our 2-facet blades provide a strong, reliable edge ideal for tougher materials. 3-facet blades, with an additional grind, deliver cleaner, more precise incisions for applications that require intricate detail. Excel Blades offers precision-ground blades engineered for superior performance.

Our 2-facet blades deliver an optimal combination of sharpness and durability, making them ideal for cutting through dense materials and tough fibers. For applications requiring the highest degree of accuracy, our 3-facet blades feature an ultra-sharp edge designed for clean, precise cuts in intricate work. For a detailed breakdown, contact us at info@excelblades.com.

Carbon steel blades are known for sharpness and edge retention, while stainless steel options offer rust resistance and longevity—ideal for wet or corrosive environments. Excel Blades manufactures blades using two primary steel alloys - carbon steel and stainless steel - each selected for specific performance characteristics.

Carbon steel, composed of iron and carbon, offers exceptional hardness and edge retention. Stainless steel, enhanced with chromium, provides corrosion resistance for extended longevity in humid or chemically sensitive environments. Contact us to learn more about our blade materials.

A degreased blade has undergone Excel Blades’ specialized degreasing process, in which all manufacturing oils, lubricants, and surface contaminants are thoroughly removed. This process is essential for cleanroom, adhesive, and food-grade applications. This also ensures optimal cleanliness and performance, particularly in precision-critical or adhesive-sensitive applications.

Feel free to contact us to explore our surface treatments.

Cleanroom-ready blades are washed and packaged in controlled environments, ensuring they meet the strict requirements for use in laboratories, electronics, and medical manufacturing. Blades designated as cleanroom-ready have been meticulously cleaned and packaged under controlled conditions, making them suitable for immediate use in sterile, particulate-sensitive environments.

This designation meets the stringent requirements of industries such as electronics, medical manufacturing, and laboratory research.

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}